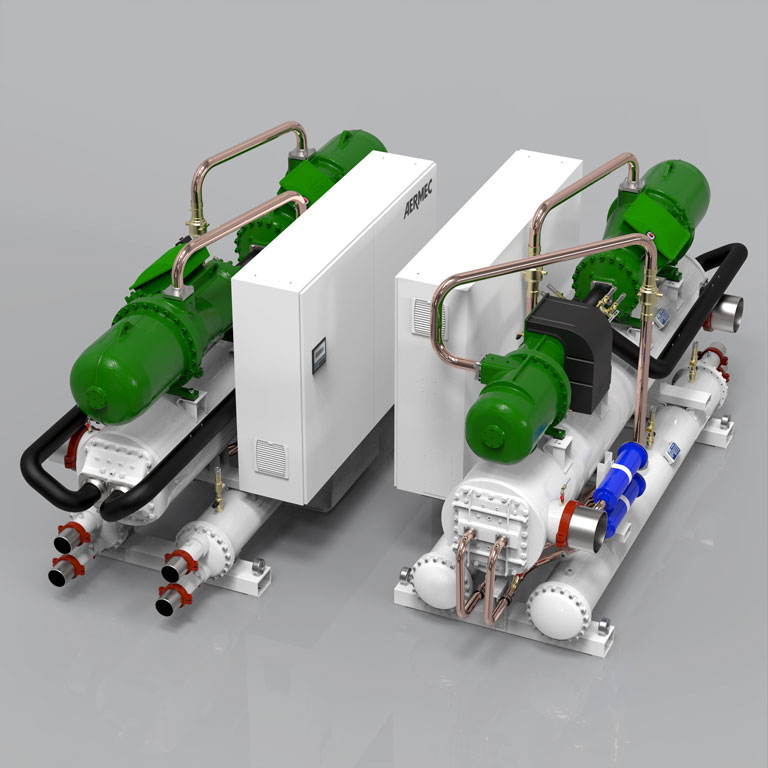

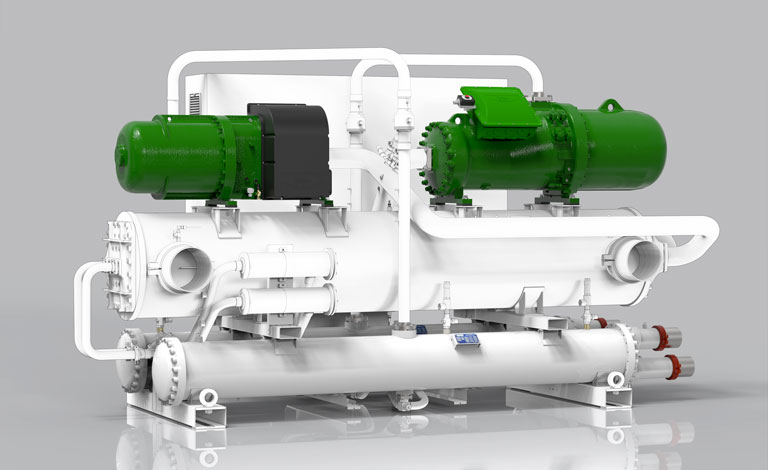

WFN, WFI, WFGN and WFGI are the latest range of water-water heat pumps designed to provide top efficiency levels but with limited overall dimensions. Made with carefully selected components and boasting a compact design, they can easily be installed even in indoor areas with little space, for both new and pre-existing systems.