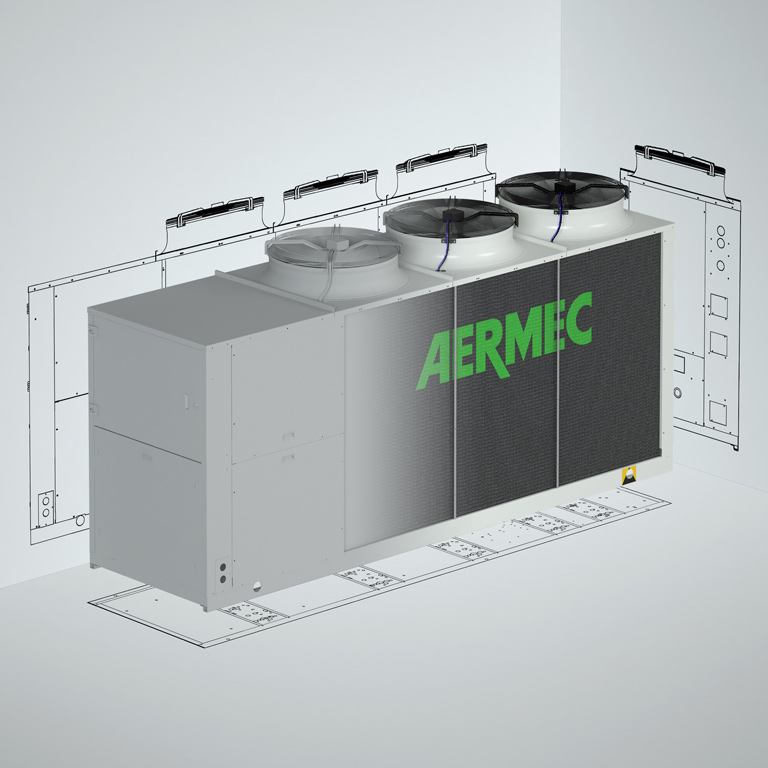

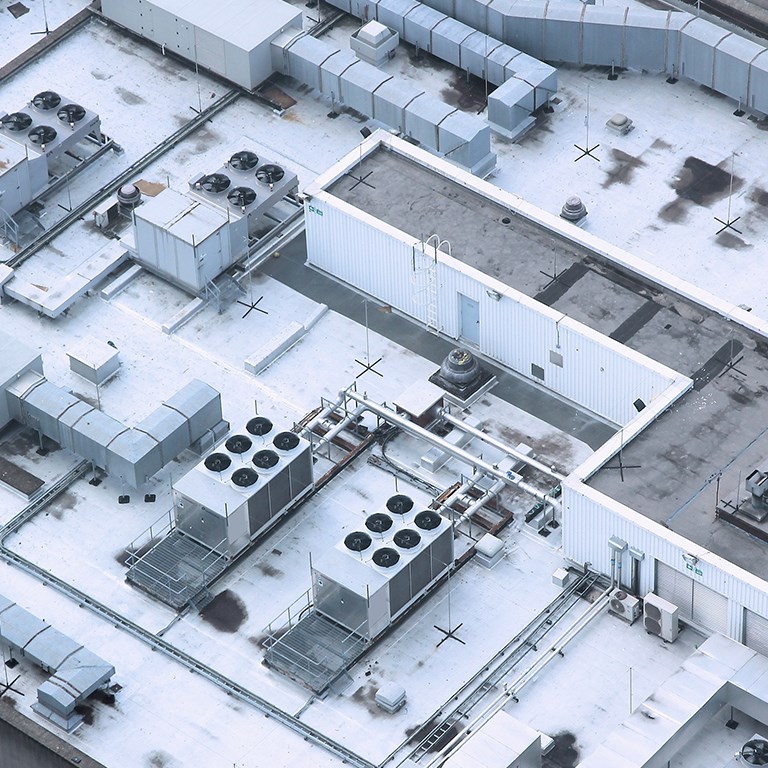

Wide selection of configurations

Cooling capacity range from 56 to 209kW and heating capacity from 58 to 191kW; 15 sizes with compact dimensions, single-circuit and dual-circuit; up to 6 versions with configurator and increasing efficiency levels to meet the requisites of European Regulation Tier 1 (in force since 01/01/2018) and ensure quiet operation. Every possible design need is fully covered.